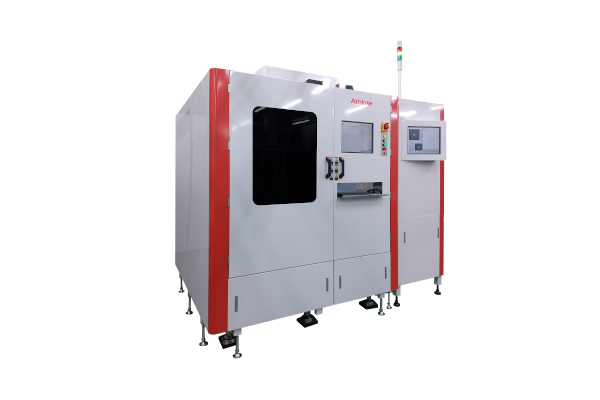

- Extremely low load, high precision bonding

- Real-time control is possible in the low load range, thereby minimizing bump height variation.

- Supports ultrasonic bonding by changing tools

- Processes supported: ACF, ACP, NCF, NCP, Au-Sn (eutectic), Au-Au (ultrasonic), solder bumping

- Various Functions & Options

<Standard Functions>

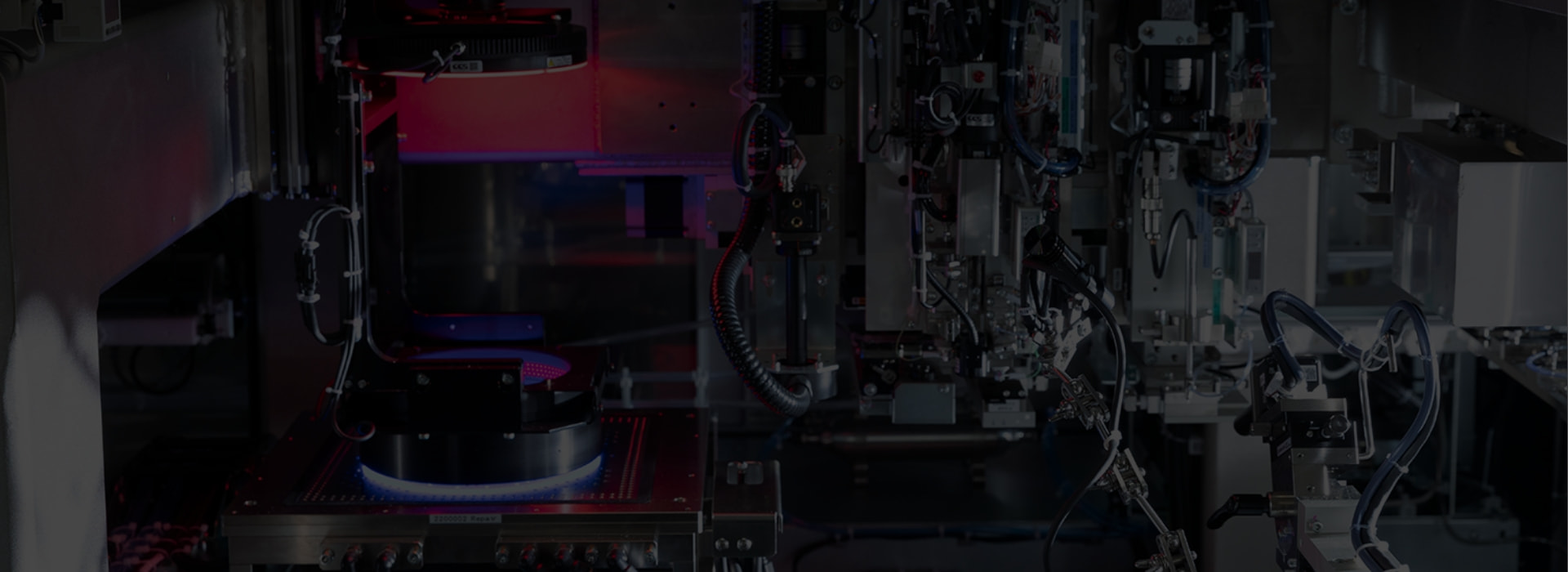

- Chip flip unit

- Constant heat stage

- ATC (Automatic Ceramic Tool Change)

- Calibration

- Process management (logger/export to other PC)

- Automatic flattening mechanism

- ID reading

<Optional Functions>

- Eutectic head (without heating)

- Purging jig for eutectic

- Eutectic stage (□52mm pulse heater)

- Transfer function (Flux, paste, etc.)

- Dispenser unit (excluding dispenser)

- Die bonder function

- Chip imaging camera

- Gel-Pack©

- Ultrasonic bonding